Wind Energy evolution: a short introduction

Wind Energy is already one of the main sources of the Electricity production mix in any modern country, together with the fossil burning, hydraulic, and nuclear plants. As a result, a whole new market has been developed, with an enormous evolution in the last 20 years.

The wind is a non-controllable energy source, and as consequence, when its participation in a country total production grew, introduced problems in the controllability of the Grid: a key subject. This problem and the need to maximize performance under extended ranges of wind speeds forced an evolution in the design of the Wind Turbine and auxiliary equipment to the actual status.

Wind Turbines are Electricity Production Plants all by themselves, designed to produce electric power whenever the adequate conditions are met, without any external intervention, adapting their behavior to the changes, and reacting properly to common negative situations (lightning, Grid short cuts, Grid voltage drops, etc.) Those are very high demanding requirement, that were fulfilled in a relative short time, creating and specialized set of industries. One important consequence of this evolution is that this market is full of ‘industrial secrets’, that Wind Turbine manufacturers tend to, logically, keep as hidden as possible.

Some references:

https://energy.gov/eere/wind/history-us-wind-energy

ACM SL approach to learn about Wind Turbine technologies

In ACM SL we have invested a considerable effort in the development of easy-to-use tools that reduce the costs (in time and money) required for achieving a throughout understanding of:

- the physical principle behind the Wind Turbine components and subsystems,

- how these components perform together to create a highly dependable Autonomous Production Plant.

Typical uptime of industrial grade Wind Turbines are in the +97%.

These tools are targeted to a broad audience, from Wind Energy Engineering students, to Wind Farm Management and Operation, to Maintenance personnel.

They are based on state-of-the-art frameworks, and consist of:

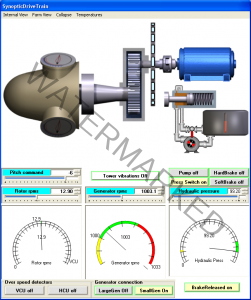

- Real Time Simulators, specific for each Wind Turbine family, and the Wind Farm SCADA Control Center.

Developed using the ‘Operator Training Systems’ methodology, so common in other industries. - Specific interactive applications: for the Drive Train, for the Electronic subsystem (Back-to-Back Converters).

- Tools for Data Analysis, both for extracting meaningful information hidden in the SCADA data,as well as from specialized data loggers, and Condition Monitoring systems.

- Specialized, interactive Tutorial, that covers all the subjects in Wind Turbines, associated with each of the Real Time Simlators and applications.

These tools are in use in Technical Colleges, Vocational Training Centers, Technical Universties and Wind Farm owners.

Courses

We offer courses specific for Wind Turbine technologies addressed to:

- Instructors of Wind Energy in Technical Colleges and Vocational Training Centers.

- Wind Farm owners.

In our courses we use our tools as well as other materials (videos, ppts, etc), and every student has a license for the simulators and applications active during the course and one additional month.

Better Wind Turbine Performance through Continuous Training of Operations and Maintenance Personnel

OpEx costs reduction by Informed Maintenance

Wind farms, as complex production plants, require a complete log of their evolution along the time. A full understanding of the causes for each entry in that log is a must for every person involved in its maintenance. So far, that knowledge is available but to a few members of the team, as the training in the inner behavior of Wind Turbines has been the privilege of few of them. This is due to the associated costs (OEMs Training costs + travel costs) and the lack of adequate training material. Also, because few OEMs are keen to explain the inner behavior of their machines, protecting it as a high valued asset.

Fortunately, this is changing, as innovative approaches address this problem, such as the ones following the field proven Operator Training System (OTS)’s paradigm, so common in other industries. This paradigm provides safe and convenient environments where trainees can observe the behavior of Wind Turbines under normal, exceptional (high wind speeds, extreme temperatures, etc.) or faulty situations, without the penalties and costs of going to the field.

An informed interpretation of the logged incidences of the plant provides additional and, in some cases, crucial information for making decisions on its operation and maintenance, becoming mandatory for the reduction of operational costs.

Improved Work Security

Working in Wind Turbines has risks associated to heights, but also to the dangerous conditions that may appear at the Nacelle, transformers, etc., due to tight spaces, high temperatures due to power dissipation, high voltages, moving parts, etc.

To get a perspective of these other conditions, let’s consider the case for the electric system (generator + power electronic) with losses of just 1% of the generated power, a reasonably small number. For a 2MW Wind Turbine, that implies 20KW dissipated in those elements; in reality a few times this value. The design of the Wind Turbine includes elements to evacuate that heat outside of the Nacelle: what happens if those auxiliary elements go off while you work up in the Nacelle? Chances are you are going to have a hard time. Fortunately, all Wind Turbine elements are supervised by the Wind Turbine Controller: one of the it’s missions is to inform you about the actual working conditions of all those elements. You should check their status before you climb the tower, but you must know how to interpret all those messages the Controller may provide to you while you are up there.

Where can you learn about those messages? Certainly in manuals; but sequences of events are difficult to explain (to say the least) in manuals or ppts. What is required is an environment where the trainee may observe different evolutions of all the elements, under realistic conditions, and as a whole working unit, not just as sets of islanded subsystems. Again the OTS paradigm is a viable approach.

“Hands-on” experience is a must for any mechanical or electric replacement inside the Wind Turbine, but exact knowledge about the “behavior” of the elements and subsystems in the Wind Turbine is equally required. On top of this, it is a must for not compromising personnel security.

Data analysis capabilities, Predictive Maintenance

Wind Turbines are robust production plants, designed autonomous operation to produce electric energy without requiring any action from any external agent. Wind Farms add additional features to Wind Turbines (reactive power compensation, overall management) complementing them with additional elements (FACTs, Substations, etc.) and management capabilities through specific SCADA systems.

Data collected by the SCADA system in a Wind Farm is received from the Wind Turbines and from the additional elements in the Wind Farm. This information constitutes the basic one for all the financial, maintenance, logistics, etc., aspects of the Wind Farm operation.

Unfortunately, not all the data inside the Wind Turbine are transmitted to the Wind Farm SCADA; typically, only management data are sent, at 10 minute intervals. This information is enough to cope with the financial statements of the operation of the plant, but fall short when you need to dig into the root causes of many problems that may arise inside a Wind Turbine.

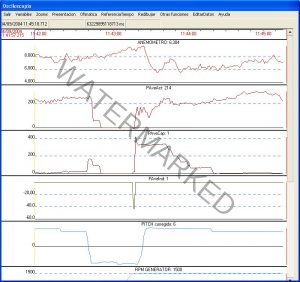

The Controller inside each Wind Turbine monitors key signals (wind speed, Nacelle orientation, electric panel, generator status, etc.) but they are not transmitted to the SCADA. Sometimes a data logger with higher time resolution (1 second or better), installed inside the Wind Turbine, is a useful tool to investigate the root causes for difficult to pinpoint problems, such as intermittent ones.

For other applications, such as analysis of the bearings and the gearbox, a very high rate data logger is used, such as the ones used for Predictive Maintenance.

All these data ask for specific and specialized analysis tools in order to obtain the maximum knowledge from them. In turn this additional knowledge will lead to better maintenance decisions at better schedules.

Proficiency with data analysis tools is also required for the personnel involved in the maintenance, operation and management of the Wind Farm.

30 seconds

Internal Training Capabilities – Corporate Universities

As the adequate maintenance and operations of the Wind Farm demands a savvy team, so it demands for tools to spread that knowledge across the organization, and to keep that knowledge updated. A practical approach is to organize them around a repository from where that knowledge can be spread out across the organization, at the appropriate levels.

The feedback from operations in the plant should have a path to this knowledge system, so they can be studied and eventually new solution patterns be discovered, and used to enhance it.

To spread out the appropriate information to each Maintenance , Operations and Management personnel level, the system should provide ad hoc channels, from direct access, to elearning channels, to Operator Training Systems feed with actual plant conditions.

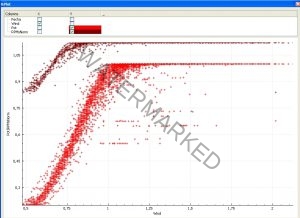

Power and Drive Train RPMs versus Wind Speed